1. How did you get into Japanese knives?

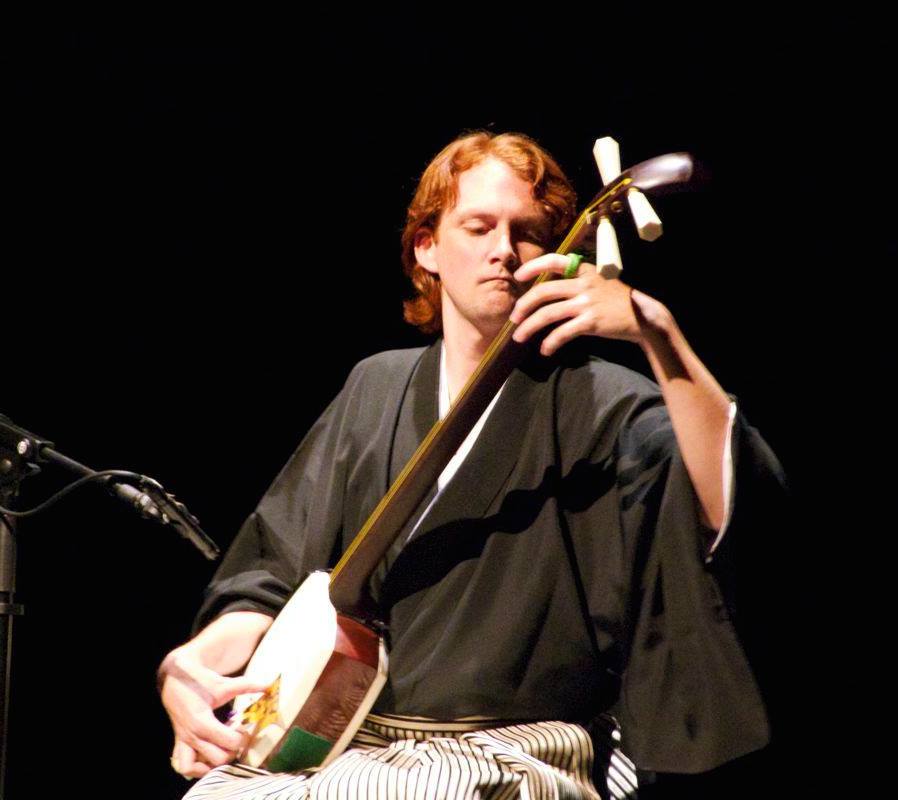

I guess it's kind of a long story of how I got into Japanese knives. I've always been fascinated with Japanese culture as a function of Japanese food being one of my favorites. This is actually what led me to get a degree in Asian studies when I attend college. As part of my studies, I spent a significant amount of time studying Japanese food. I even went as far as to write a thesis on a particular type of Japanese food-sukiyaki and shabu shabu. I think it's almost inevitable that if you study Japanese food you end up learning about Japanese knives, since skill and technique is such a large part of what makes Japanese food so great. While attending college, I started cooking professionally. This only amplified my interest in Japanese knives, and I soon found myself using primarily Japanese knives at work. Sometime later, I had an opportunity to cook in Japan. While training there, I asked my chef to teach me about sharpening and knife skills relating to the two Japanese knives. This was the beginning of my obsession. From there it grew and grew, and eventually became the business that I run today. Now, I have the opportunity to train in Japan the crowds and make these knives every year. Being able to see both the craftsmen side of the knife making process as well as the end-users using their knives and professional kitchens is something that I find extremely interesting.

2. What are some advantages of Japanese knives?

Japanese knives tend to be thinner and harder than their Western counterparts. There are some benefits to this, as well as some costs. Because Japanese knives tend to be a lot thinner, they move through food with much less resistance. For many people, this means that they feel sharper. However, being thinner also means that they lose out in structural stability a little bit, and are much more prone to chipping and similar damage. Being harder translates into Japanese knives holding their edge for a longer period of time and being more capable of holding acute angles. The acute angles translate into a generally sharper feeling. However, the trade-off for these things is that as the knives become harder, and as we sharpen them at more acute angles, they are more brittle, which contributes to the chipping problem previously mentioned. So, in some cases Japanese knives can be excellent, assuming that the knife skills, care, technique and use, and maintenance all come together to support the use of Japanese. One other interesting thing about Japanese knives is the way that the knife makers approach the heat treatment process. Japanese knives tend to be very finely grained, and the heat treatment is geared more towards grain fineness and edge retention than toughness and durability, which is in stark contrast to the kinds of heat treatment we see from knife makers in the Western world. Japanese single bevel knives have the benefit of being much more acute in terms of their overall angle, and having a unique cross-sectional geometry that provides a cutting experience unlike anything else. Most Japanese single bevel knives are designed for very specific tasks, and when used appropriately for those tasks, they are excellent. However, as general use knives, they are rather clumsy and difficult to use. For example, a deba is probably my favorite knife for breaking down fish, but it makes a very poor chef's knife.

3. Which knives do you recommend for someone new to Japanese knives?

In general when people come to Japanese knives for the first time, it's my tendency to recommend to them something that is stainless and relatively tough and durable within the scheme of Japanese knives. There are many carbon steel Japanese knives (which means that they are prone to rusting and can be reactive with acidic foods), but in the beginning, as people are learning about how to use and care for Japanese knives, I prefer to minimize the kinds of things that they have to worry about so that they can focus just on cutting technique and basic sharpening. The type of handle that I might recommend depends predominantly on end-user personal preference. I personally tend to prefer Japanese style handled knives, but there are many who still prefer Western-style handled knives. Japanese-style handled lives tend to be lighter overall, and have a more forward heavy balance. Western-style handled knives tend to have a balance point more near to the poster and are generally have your overall. I will often recommend one big knife and one small knife. The big knife is more often than not a gyuto, while the smaller knife is generally a petty knife. Size wise, the larger knife will often run from 210 mm to 270 mm, while the smaller knife will often be around 150 mm. One of the brands that I recommend most often from the knives that we carry is the Gesshin Uraku Stainless Series. They are exactly what I have described above - lightweight, stainless, tough and durable, and come with a Japanese-style handle and a very Japanese-style profile. They also happen to be rather reasonably priced, and I think that it's important to start off with rather simple things and learn how to use them before moving on to higher and things. It's my experience that the more money you spend on things, the more that is required of you as an end-user, skill wise and experience wise, in order to use, care for, and get the most out of that item.

4. What other tools and accessories would you recommend?

There are a number of other tools that might be helpful for people getting started with Japanese knives, but again, I like to keep things as simple as possible. I think that a big knife, small knife, and a very basic sharpening set up is probably everything that people need to begin with, and is often more than enough for people forever. In a complete sharpening set up one might have the following things:

• A good coarse stone (from about 220 grit to about 600 grit, although a little bit lower or little bit higher is not the end of the world) - this stone is used for major repairs, chips, extremely dull knives, thinning, etc.

• A good medium grit stone (from about 800 grit to about 2000 grit) - this stone is used for day to day sharpening, and can also be used for minor chips, minor repairs, and is often the place most people begin their sharpening routine.

• A good finishing stone (from about 3000 grit to about 8000) - this stone is used to give your edge a little bit more refinement, make the burr removal process a little bit easier, and improve the aesthetic finish of the edge.

• Something to hold the stone in place - as simple as this sounds, this is actually very important. Although this doesn't need to be fancy, there are extremely fancy setups out there for this. This can also be as simple as a damp towel on the corner of your countertop, holding the stone in place ensuring that it's a stable base for you to sharpen on while you're moving a sharp object over it repeatedly. Fancier stone holder setups will also provide additional stone height, which can help create knuckle clearance. They may also offer some kind of solution for collecting the mess that occurs during sharpening, which makes cleanup easier at the end of the day.

• Something to keep your stone flat - as we use the stones, they tend to dish. Having a stone that does not have a flat surface makes it extremely difficult to maintain a consistent angle. Maintaining a consistent angle during sharpening is one of the most important things that we can do during sharpening. Keeping our stone surface flat is a large part of that. This, again, can be a rather expensive solution, or something almost entirely free. For example, I use a diamond flattening plate to keep my stones flat. They run about $65. On the flipside, one can use the sidewalk in a pinch, or wet/dry sandpaper inverted so that the grit is facing up. With the sandpaper laid down on a flat surface, and the grid facing up, one can rub the surface of the stone on the sandpaper to flatten the surface of the stone. If one has carbon steel knives, a rust eraser and camellia oil might also be helpful.

5. What are some common mistakes people make with Japanese knives?

I think there are two main areas where common mistakes occur - knife skills and sharpening problems. The knife skills required when using Japanese knives differ slightly from those used with German knives or other Western knives. Because the knives are so much thinner and harder, the rocking motion that is often taught tends to actually cause damage to Japanese knives. We use a thrust cutting motion that pulls the entire edge of the blade off the cutting board during each cut, which minimizes lateral force exerted against the edge. The main causes of damaged Japanese knives are as follows: hitting extremely hard things, hitting things with excessive force, and lateral force exerted against the edge. The knife skills that we use with Japanese knives try to minimize these things. With regard to sharpening, the biggest mistakes that I often see are not forming a burr, not getting rid of the burr once it has been formed, or forming an inconsistent burr over the length of the knife, causing the profile to change over time. Carbon steel knives can also often present problems for people. Not cleaning and drying them properly can cause the knife to rust. And, when working with acidic foods, not wiping off the blade periodically will result in both the blade and food oxidizing significantly, causing color, taste, and smell changes to the food, and rapid patina development on the knife.

6. How can people learn more about Japanese knives?

Nowadays, there are number of ways that people can learn about Japanese knives. There are a number of online forums that provide great resources. There are also books available in English as well as a number of videos on YouTube. For instance, we have about 3 1/2 hours of videos covering every topic that one might need to know about knife sharpening available on YouTube. Between all of these resources, it's rather easy to get out there, ask questions, and get a good idea of where you might want to start personally. Also, I try to make myself personally available to people as much as possible so that I can answer questions and help people get started with Japanese knives. As a function of our day-to-day business operations, we probably spend more time educating and teaching people than anything else.